Recycling

Waste to Energy

Waste treatment plant

Sanitation of dumpsites

RDF & SRF fuel Brokers

The idea

Our project start from the idea to realize an INTEGRATED SYSTEM for THE TREATMENT and RECLYCLING of EXPOITABLE FRACTIONS and FINAL STORAGE of INDUSTRIAL NON HAZARDOUS WASTE.

By the use of our exclusive technology as PHARAON® for the selection of the exploitable fractions in the waste we are able to minimalize the quantity of waste to be storage in the landfill and also with the MATRIX SYSTEM® , that is exclusive patented part of our plant , we will storage only STABILIZED WASTE.

What We Do

Our Technologies

Reverse.

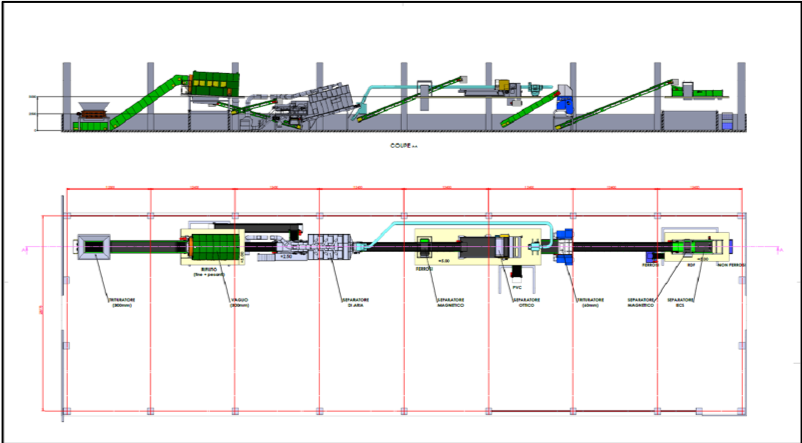

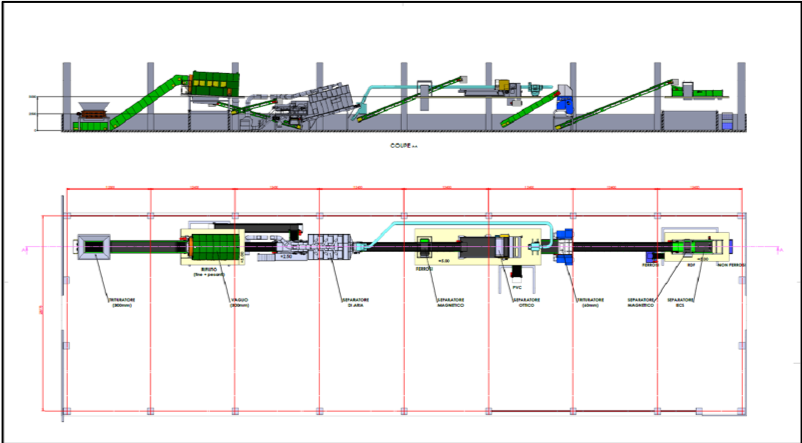

REVERSE®: Treatment of Industrial non-hazardous

Waste - Recycling and production of RDF/SRF

The treatment of inert and industrial non-hazardous waste in the REVERSE technology line includes the following activities:

Fractional separation of size> 300 mm;

Fractional separation of size <100 mm;

Separation of non-ferrous metals;

Manual selection of waste from plastic strips and containers in the primary selection section;

Alternative fuel production (RDF/SRF) with granulation of 0 - 50 mm;

Landfilling of the residue

Production line capacity: 20 tons / h.

Environmental benefit

Decrease quantity of landfill waste;

Allow a recycling of the waste to produce an alternative fuel

Recovering the usable fractions of the waste using Reverse

Reverse

UNIQUE AND PATENTED PLANT WITH INNOVATIVE WASTE PROCESSING TECHNOLOGY KNOWN AS S.M.S

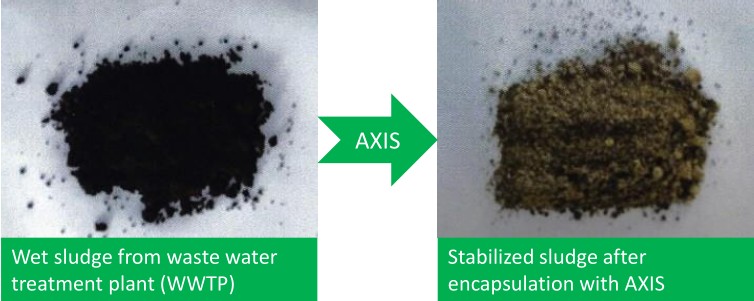

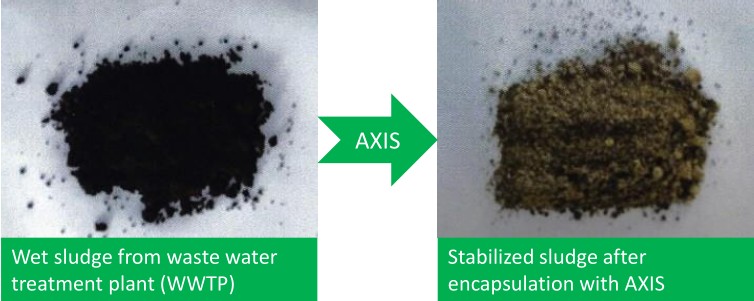

AXIS:

STABILIZATION

MICROENCAPSULATION

SOLIDIFICATION

For each type of waste, a dedicated technology Mixed non hazardous industrial waste: REVERSE® Mechanical sorting of mixed waste in order to recover metals, plastic and paper. Production of RDF Sludge from Waste Water Treatment Plant: AXIS® By the use of our exclusive technology as AXIS® we are able to treat the not hazardous SLUDGE from the different type of INDUSTRIES and after SMS ( Stabilization –Micro-encapsulation – Solidification ) the stabilized waste could be landfilled safely.

Such process consists of the transformation of both solid and liquid wastes into a stable material, having constant physical characteristics, which can be used for some production cycles with a further cost decrease for the company involved. Further more, thanks to its technical characteristics, its small dimensions and low energetic demand, the AXIS® plant can be used for on site contaminated soils reclamation in order to obtain a recyclable product.

Stabilizing sludge by encapsulation

AXIS

Pharaon.

Plant for treatment of Municipal and Industrial Non-Hazardous Waste

Recycling solution for the production of SOF and RDF

In the 1st phase, the dry fraction is separated from the organic fraction and directly transported from the plant.:

Dry fraction

Dimension > 50 mm

destination: Recycling/Production of RDF/SRF

Organic fraction:

Homogenized and treated to obtain the stabilized organic fraction (SOF)

The SOF which has a fixed granulometric composition is loaded directly into transport vehicles without interim storage to be used as recycled composting material

SOF: Dimension 20/40 mm / Destination: Recycling.

Pharaon

Pharaon

WHAT IS MATRIX®

MATRIX® is a rapid installation, transportable mobile system designed for treating organic waste derived from MSW and biological sludge to obtain SOF

(Stabilised Organic Fraction).

WHY MATRIX®

To stabilize MSW, making safe

To reduce waste treatment time to a minimum

To get good quality material output

To significantly reduce waste volume

Because of its low atmospheric emissions

HOW IT WORKS

The MATRIX® process uses CaO (Calcium Oxide) in a two phase process:

Stabilization: addition of materials which ensure that dangerous substances in the waste are kept in a state of low solubility, mobility and toxicity.

Micro-encapsulation: contaminants are mechanically captured and encapsulated inside the solidified matrix.

ARCHITECTURE

The machine is divided into three main sections that distinguish the three phases of the process, from MSW input to SOF output

1.MIXING

2.MATURING

3.COOLINC

Matrix

Matrix

Balling the municipal waste

Municipal Solid Waste

Light industrial waste

Agricultural products

Waste treatment problems

Animals:

Rodents, birds, flies, mosquitoes

Fire

Burning landfills

Contamination Smells, leachates

Results

Lowering of living standards

Devaluation of property values

Spoiled touristic sites & beaches

Costs

Specialized waste transport vehicles

High transportation costs

High storage/handling costs

Leachate collection systems

Leaking landfills

Fire Safety measures

Round bale advantages

Air pockets are “rolled out” during bale formation

Free Oxygen content is minimized

Moisture reduction in the rolling process

Bale contents are homogenized

No leachate during round baling

LDPE-foil to seal bales air & water tight

No leachate in the stack.

No more food available for animals.

Significant waste volume reduction - High density

Bale chemistry - contents biologically inert

No methanogenic activity inside the bale

No fires for spontaneous combustion.

Bale contents retain original high-calorific value

Round bale has no vulnerable corners.

Optimized use of landfill

Sanitation of existing dumpsite

Transporting balls

Our Products

RDF means ‘Refuse Derived Fuel’. This is an alternative fuel.

This is a secondary material made from sorting of waste.

Its composition is a mix of paper, plastic, textile, rubber, wood.

RDF is widely used in Western and Northern Europe. In Germany, it is substituting up to 70% of fossil energy (coal and fuel oil) in the cement industry.

Using RDF is beneficial for the environment:

* Decrease quantity of landfill waste;

* Produced locally from local economy;

* Circular economy;

* Very competitive and stable price (not linked to the petroleum prices).

Additional information on RDF

SRF

Solid Recovered Fuel (SRF) is a “solid fuel prepared from non‐hazardous waste to be utilised for energy recovery in incineration or co‐incineration plants, and meeting the classification and the specification requirements laid down in EN15359

Environmental benefit

Decrease quantity of landfill waste;

* Circular economy;

Very competitive and stable price

Prevents air pollution: SRF has lower greenhouse gas emissions than coal or petcoke

SRF

SRF

RDF & SRF fuel Brokers

Hazardous/Non-Hazardous waste export in EU and Non EU countries

CONNECTION WITH

- Power plant

- Cement factory

- Plant for treatment

FOR

- Waste to energy R1

- Waste for recycling and reuse R12

WE TAKE CARE OF

- Transport by truck or ship

- Control of loading process

- Document for final dismissing

CONNECTION WITH

- Power plant

- Cement factory

- Plant for treatment

FOR

- Waste to energy R1

- Waste for recycling and reuse R12

WE TAKE CARE OF

- Transport by truck or ship

- Control of loading process

- Document for final dismissing

Environmental Benefit:

Protecting the Environment

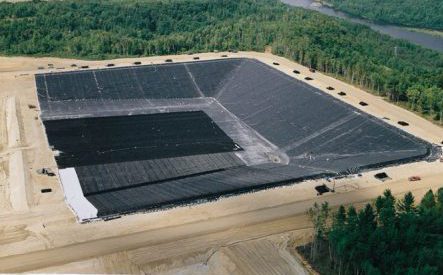

Controlled landfill prevent potential pollution of the underground water (which is not the case when waste are dumped in uncontrolled way in the nature) Our landfill is designed and built according National and European rules (geo-membrane, drainage, monitoring) No smell, no dust, no industrial waste polluting near the facilities.ECONOMY : industries will be educated to invest in a country with clear rules.

FUTURE GENERATION : they will not find contaminated uncontrolled Landfill.